The movement to america

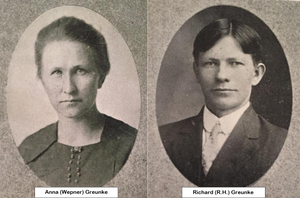

Our story begins in 1882 when Frederick and Ernestine Greunke emigrated from their native country of Germany to the Dupont Township of Waupaca County, Wisconsin. As many new immigrants of the time did, they bought a small family farm where they worked and raised their 8 children. As their children grew, two of their sons started to experiment with the making of cheese. The two sons, Richard (R.H.) and Otto, started selling of the cheeses they produced in mid-to-late 1911. Just prior to his experimentation phase with cheese, R.H. married Anna Wepner in 1906 and began building a family of future cheese makers.

The Beginning

In November of 1911 Richard traveled to Madison, Wisconsin and enrolled at the State Agricultural School for their course in dairying. Upon completion of the course in early 1912 he set out to apply his new knowledge in cheese making and bought a small cheese factory in the town of McMillan in Marathon County, Wisconsin. After two short years in McMillan R.H. and his family moved to the Milladore Township in Wood County and bought a local cheese factory known as Brookside Cheese Factory from Elmer Hitzke on March 1st, 1915. With his families support R.H. would work towards mastering cheese making and building a business, with the move to Brookside often being referenced as the start of it all. The Brookside factory, which most would confuse with a normal home, was the living quarters for the family upstairs and the production area for cheese downstairs.

The growth begins

As R.H. and family worked towards mastering their craft in cheese making the company growth followed. By the year 1920 Richard recorded purchasing 1,742,265 pounds of milk and manufactured roughly 166,821 lbs of cheese. An important factor for the success of a cheese maker is called the cheese yield which determines the pounds of milk it takes to produce one pound of cheese. In 1920 R.H. achieved a cheese yield of 10.44:1. Along with the business growth, Richard and Anna Greunke also saw family growth. By the end of the 1920's the family was complete with a total of 12 children having been born. The children were as follows: Ella M., 1907; Alma M., 1908; Leonard A., 1910; Erma A., 1912; Estelle A. E., 1914; Helen P., 1916; Viola M., 1919; Armin R., 1921; Richard M., 1923; Orville V., 1924; Ceylon L., 1927; Delbert L., 1929.

The Start of a New Chapter

With plenty of mouths to feed and even more hands to help, the 1930's and 1940's brought rise to an entire family of cheese makers. As soon as each of R.H. and Anna's children reached their preadolescence years and were able to provide a helping hand, they were each given chores to help with the work. A full family affair, the children each had tasks they helped with both before and after school to make sure all the work was getting done. In 1940, with R.H. being 60 years old, the transition years to the next generation of cheese makers began. Sharing his decades of knowledge to his children they began to run the operation with guidance from their father. In 1948 Richard, Ceylon, and Delbert took over day-to-day operations of the company. By 1953 Ceylon bought out his other two brothers, took over the management of the cheese making, and bought a new, larger building to use as the production facility.

New Location, Same greunke's Cheese

In 1953 Ceylon moved the cheese factory to 10498 Mayflower Road, Milladore, WI. During this transition there was also a change in name from Brookside Cheese to Maple Grove Cheese. With the new found space to work with, Ceylon continued to increase production over the next few years and added an addition onto the new cheese factory building in 1959. A few short years later in 1964 a change of hands of ownership occurred again when Richard (Ceylon's older brother) acquired the factory and took over production. Due to some financial hardships of the time, Richard downsized production and for the next couple of years did all of the cheese making with his wife Ardis. Prior to re-entering the cheese making business Richard had stepped away, gotten married to Ardis, started a family and worked as a mink farmer and butcher to support his family.

A shift in approach

As Ardis and Richard continued to work hard making all the cheese themselves with support from their older children, they were able to get the company in a stable condition again and purchased a brand new milk can hauling truck for $3,300 in 1967. As a part of the cheese making process the Greunke's would purchase milk from local farms in order to make into cheese. At each farm the farmer had filled cans already there from the milking of their cattle the night before and the milk man would swap out the full cans of milk with the empty cans. As technology in automobiles and more robust electric power became standard place in in rural America, a disruptive leap in technology occurred in 1969 for Maple Grove Cheese when they purchased their first bulk milk hauling truck. This new technology meant the farmers now had one large "bulk" tank that all the milk that was gotten from the cattle was stored and cooled in. When this occurred Richard was able to get rid of the milk cans and able to get a truck that also had one big tank to store all the milk. The milk man would then utilize a pump that was on the truck to pump all the milk from the farmers tank into their truck and eventually into the cheese factory. This laid the foundation for making huge steps in the massive growth in the production quantities of cheese to lead to an era of true mass production at scale.

The 3rd Generation

As Richard and Ardis' business continued to grow, similar to their parents generation, so did their family. By the early 1970's all of their children were born and many of the older children were supporting the actual cheese making themselves before they would head off to college. Ardis and Richard Greunke had 9 children as follows: David, Steve, Mitch, Rosanne, Scott, Alan, Sandy, Kathy, and Sara. In 1972 Richard invested in his first finishing table for cheese making and also purchased a new, larger vat. Prior to this time the entire cheese making process was completed in one, open topped tank called a cheese vat (often referred to presently as an "open vat"). With the addition of a cheese table the matting process and final salting processes could be done in a separate location for ease of handling. This is also a first glimpse at an active assembly line approach in the factory where multiple vats could be in production at the same time.

The work continues

As Maple Grove Cheese continued to perfect it's craft, bacterial research became a focal point for the dairy industry. During the late 1970's many college and dairy research labs were focusing their efforts on better understanding and refining the application of bacteria to milk to produce cheese and how it could be manipulated to make different kinds of cheese at larger quantities. This led to more reliable bacteria starter cultures and more robust systems to make larger batches of cheese. In 1989 Richard added on to the cheese plant adding a new room on the facility with two whey tanks as well as a tank to store cream. The whey separator was also moved into this room and allowed for an area to pump whey that was later run through the separator to get the by-product of cream. In that same year, at the age of 65 Richard handed over the daily operations of the cheese plant to his son Alan. Alan, having grown up and working in the cheese factory his entire life, is the youngest cheese maker in Wisconsin history having been licensed in 1972 by the state of Wisconsin at the age of 13. Over the next 20 years Richard continued to come to work in the cheese factory as the resident cheese cutting expert to ensure there was plenty of cheese in stock for locals who wanted to come in and purchase a pound or two. Richard embodied the true Wisconsin Artisan cheese maker culture by spending over 70 years of his life making and perfecting the craft for future generations before his death in 2020.

Technology is the new Mindset for Expansion

Two short years after taking over operations from his father, Alan made his first major upgrade to the cheese plant equipment. In 1991 he purchased three 20,000 lb open vats and two finishing tables which allowed for larger amounts of cheese to be made at once. A few short years later in 1995 he replaced these three open vats with two new Double-O style cheese vats. These newer styled cheese vats, which no longer fell into the "open vat" category due to them being totally enclosed, were eventually controlled by PLC powered automation. This automation allowed for these vats to be larger, with both of the vats having a capacity of 35,000 lbs, while still significantly reducing the labor required to make the cheese. When these new vats were purchased Alan also had one of his finishing tables extended in order to fit the volume of cheese from the larger vats. With this setup the first 2.5 hours of the cheese making process could be done almost completely inside the vat with very little user input to ensure a consistent, quality product. With these exciting additions to his craft, Alan also had additions in his personal life when he married his wife Joan in 1992. Two years later they would begin a family of 4th generation cheese makers. Alan and Joan still own and operating the factory today.

The mass production Mindset

The next few years, as Alan and Joan were starting a family, the history of Maple Grove Cheese was defined by consistent additions and growth with a heavy focus on technology. These updates were led in 1999 with the addition and purchase of block forming towers, an additional Double-O cheese vat, and a new longer finishing table. The addition of the block forming towers, which were automated machines that would press, size, and cut the cheese into 40 lb blocks, was the last leg to having a true continuous, flow mass production cheese setup. With this setup Alan and crew were able to make the same amount of cheese in two weeks that his grandfather, R.H. Greunke, made in an entire year. Following this in 2004 and 2005 the Greunke's acquired a new self cleaning separator to handle the larger capacity and their first milk silo that could hold roughly 175,000 lbs of milk. In 2008 another milk silo was purchased and installed to bring the total storage capacity for milk up to roughly 350,000 lbs. In 2009 a new wing was added to the cheese plant where the existing Double-O vats along with two new Double-O vats would be operated. By this time Alan and Joan's family was complete and subliminally learning the cheese making process themselves. Their three children were Kyle (1993), Jordyne (1996), and Brett (1998).

The Mark of a Master

In 2010, as Alan continued to work to improve his product and expand his knowledge in cheese making, he enrolled in the coveted Wisconsin Master Cheesemaker® program that is sponsored through the UW-Extension, Center for Dairy Research, and the Dairy Farmers of Wisconsin. This program has developed and produced global, award winning cheese makers and is the only advanced education program of its kind with a focus on experts in the craft of cheese making in the United States. With fewer than 80 people in the world holding the coveted title of Master Cheesemaker, the program participants are required to take educational courses that cover all aspects of being an expert cheese maker, participate in annual cheese evaluations from a designated committee to ensure the cheese produced is of appropriate quality, and take a final exam that can take up to 40 hours to complete to prove their expertise in the field. Alan graduated from the Wisconsin Master Cheesemaker® program in April of 2013 with Master Certification in Cheddar and Monterey Jack Cheeses. The work of a Master Cheesemaker can be determined from the Master's Mark.

A focus on Artisanship

With the advent of the world-wide COVID-19 pandemic, we (The Greunke's) have taken a step back to revisit the art of making cheese and endless pursuit to the perfection of the craft. In 2020 and 2021 we cut back on mass-production operations and purchased smaller open vats to produce more custom batches of artisan cheese. With this new equipment and re-frame of approach we are working to expand our cheese varieties and flavors for our customers. Interested in what types of cheeses we are digging into now? Visit the online cheese store to find out!